201 stainless steel round bar

Langsda Metal Products Co.,Ltd supply type 201 Stainless Steel is an austenitic chromium-nickel-manganese stainless steel which was developed to conserve nickel. Type 201 is a lower cost alternative to conventional Cr-Ni stainless steels such as 301 and 304.

Description

201 stainless steel is an alloy that contains half the nickel and increased manganese and nitrogen of more popular steels.

Type 201&202 is an austenitic metal because it is a non-magnetic stainless steel that contains high levels of chromium and nickel and low levels of carbon.

SPECIFICATIONS

Type 201 Stainless Steel is covered by the following specifications:

ASTM A240

Chemical composition

C | Si | Mn | Cr | N | P | S | Ni |

≤0.15 | ≤0.75 | ≤5.5-7.5 | 13.5-15.0 | ≤0.25 | ≤0.060 | ≤0.03 | 3.5-5.5 |

Typical Mechanical Properties

Tensile Strength | Yeild Strength | HBS | HRB | HV | Density |

≥520MPa | ≥415MPa | ≤207 | ≤95 | ≤218 | 7.93g/cm3 |

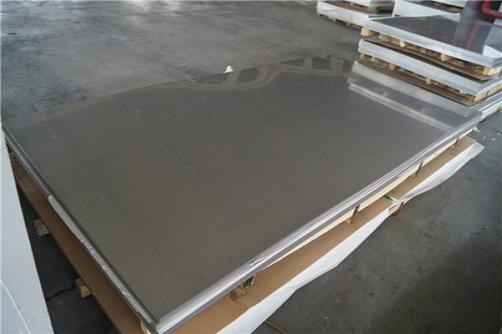

Surface--stainless steel plate/sheet/coil

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Application

Type 201 is used to produce a range of household appliances, including sinks, cooking utensils, washing machines, windows, and doors. It is also used in automotive trim, decorative architecture, railway cars, trailers, and clamps. It is not recommended for structural outdoor applications because of its susceptibility to pitting and crevice corrosion.