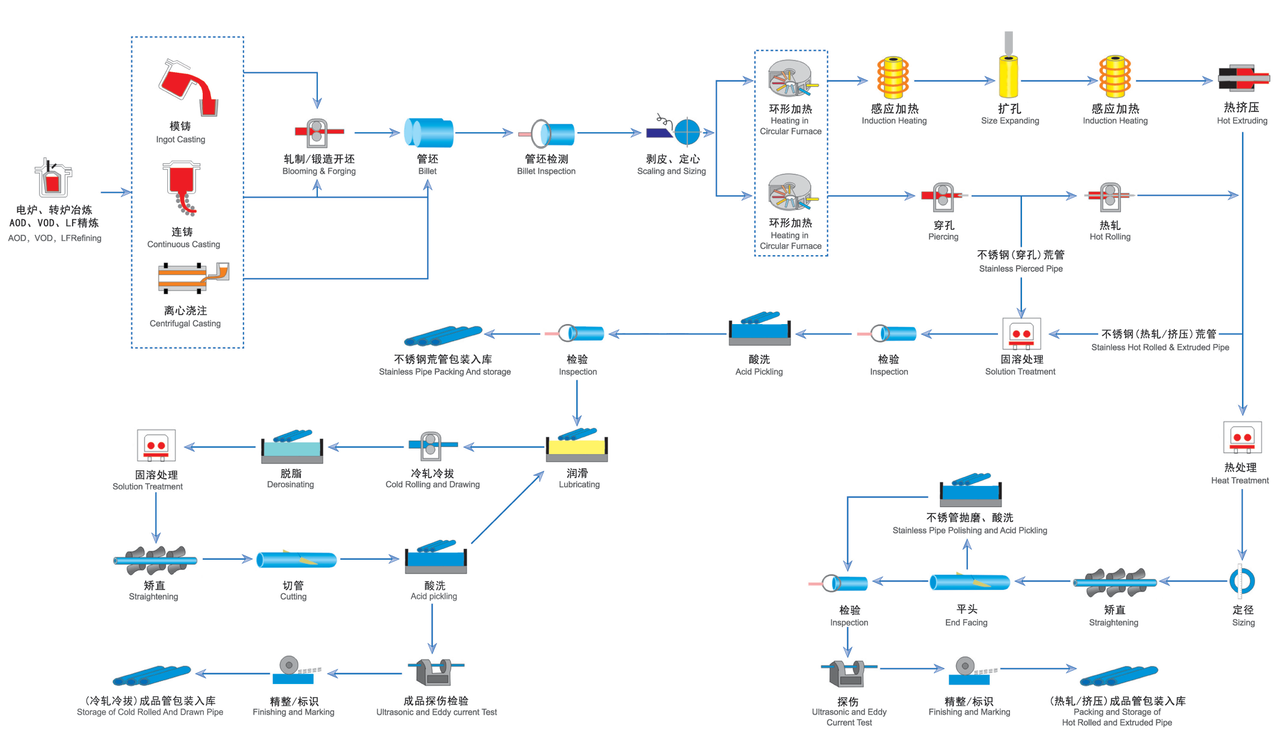

Production Process

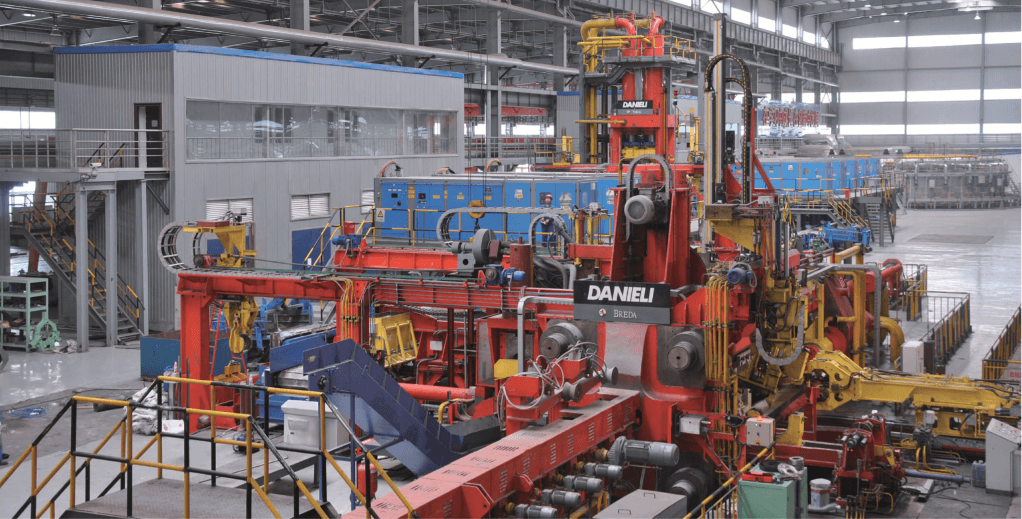

Production equipment of hot extrusion

Equipment

63MN horizontal hot extruding press

25MN vertical reaming machine

14m circular furnace

Induction furnace x 7

10MN pressure straightening machine

Equipment parameters

Extrusion pressure:63MN

Specifications: DIA 76-325mm x 4.5-60mm

Length:4-24m

Precision:OD±1%, WT±8%

Main products

Stainless steel, Duplex stainless steel, High-alloy steel, Nickel-base alloy, Anticorrosion alloy, Metallurgical Bi-metal pipe and seamless tube&pipe and heteromorphism materials etc.

Production equipment of cold rolled and cold drawn

Equipment

LG series cold rolled mill

YLB,LB series cold drawn mill

Straightening machines series

Equipment parameters

Outer diameter of the finished steel tube is DIA25-245mm

Wall thickness is 1-22mm

Main products

Stianless steel, Duplex stainless steel, High-alloy steel, Nickel-base alloy,Anticorrosion alloy and Metallurgical Bi-metal pipe and seamless tube&pipe etc.

Heat treatment equipment

Solution furnace

Brighten and heat treatment furnace

Equipment parameter

Max temperameters: 1280℃

Solution specificaion: DIA 20-325mm

Brighten and heat treatment specificaion: DIA 20-76mm