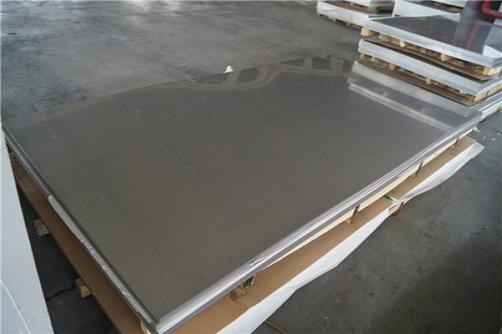

310S Stainless Steel Coil

Langsda Metal Products Co.,Ltd Having a good oxidation resistance, corrosion resistance and high temperature resistance because of a higher percentage of chromium and nickel, 310 has much better creep strength, is able to operate continuously at high temperature, and has a very good high-temperature resistance.

Grade 310 resists oxidation and is also used at temperatures up to 1040 degrees Celsius intermittently. Similar to other austenitic steel grades, toughness down to cryogenic temperatures is another feature of 310.

310 UNS S31000 Chemical Composition, %

Cr | Ni | C | Si | Mn |

24.0-26.0 | 19.2-22.0 | .25 Max | 1.50 Max | 2.00 Max |

P | S | Mo | Cu | Fe |

.045 Max | .03 Max | .75 Max | .50 Max | Balance |

310S UNS S31008 Chemical Composition, %

Cr | Ni | C | Si | Mn |

24.0-26.0 | 19.2-22.0 | .08 Max | 1.50 Max | 2.00 Max |

P | S | Mo | Cu | Fe |

.045 Max | .03 Max | .75 Max | .50 Max | Balance |

Mechanical Properties

Representative Tensile Properties

| Ultimate Tensile Strength, ksi | .2% Yield Strength, ksi | Elongation Percent |

70 | 80.0 | 35.0 | 52 |

1000 | 67.8 | 20.8 | 47 |

1200 | 54.1 | 20.7 | 43 |

1400 | 35.1 | 19.3 | 46 |

1600 | 19.1 | 12.2 | 48 |

Typical Creep-Rupture Properties

| Minimum Creep 0.0001%/hr, ksi | 100,000 Hour Rupture Strength, ksi |

12000 | 14.9 | 14.4 |

1400 | 3.3 | 4.5 |

1600 | 1.1 | 1.5 |

1800 | .28 | .66 |

Features

1.Good resistance to thermal fatigue and intermittent heating at high temperatures.

2.Good aqueous corrosion resistance due to high chromium content

3.Excellent resistance to an oxidizing and carburizing atmosphere.

4.Resists nitric acid fuming at normal temperature and fused nitrates to temperatures upwards of 425 degrees Celsius.

Applications

Automobile Industry, Construction, Pharmaceutical / Chemical Industry, Oil & Gas Industry